For centuries, archaeologists have pieced together fragments of the past with little more than brushes, glue, and patience. The reconstruction of broken statues, eroded pottery, and crumbling temples has always been as much art as science — guided by intuition as often as by evidence. But today, a new ally has entered the field of archaeology: 3D printing. With this technology, lost civilizations are being reborn not just in museums, but in digital form — one microscopic layer at a time.

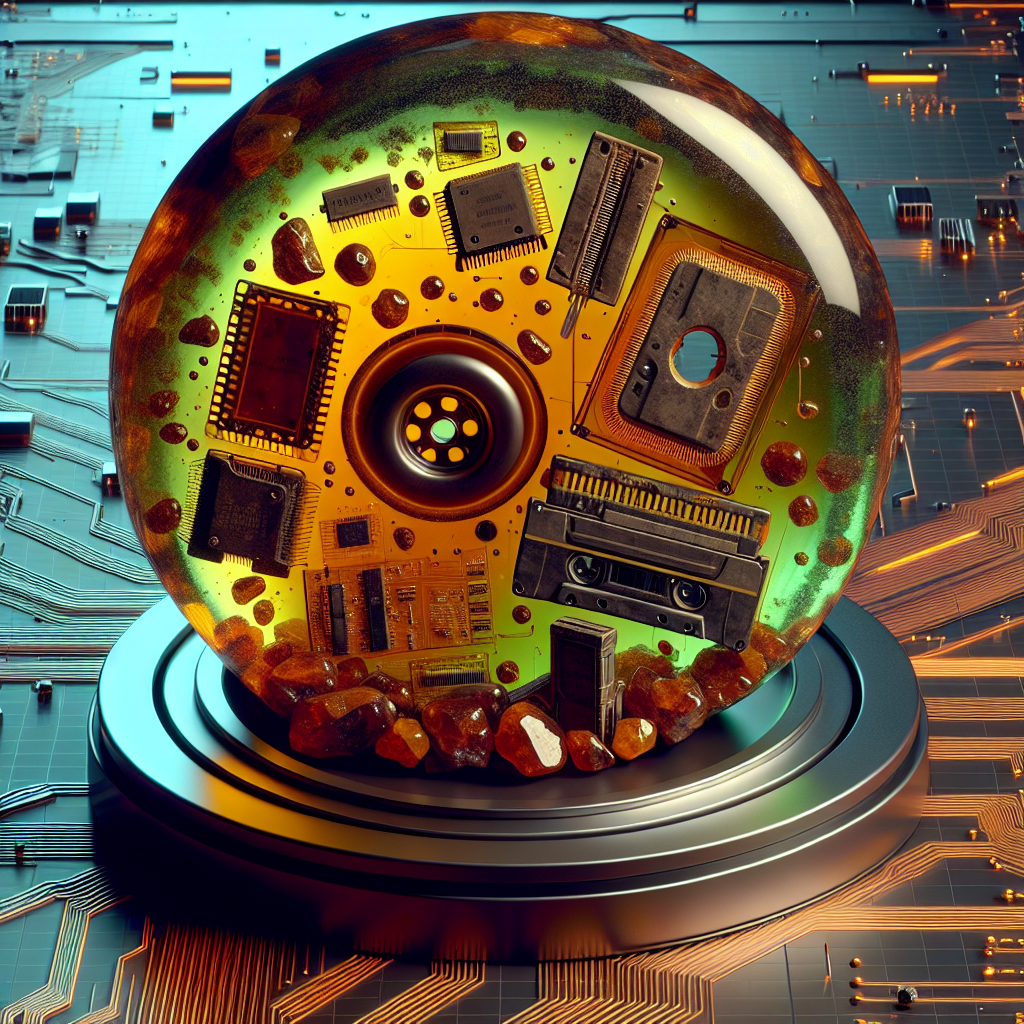

At its core, 3D printing, or additive manufacturing, is deceptively simple. A digital model is created using 3D scanning or computer design, and a printer builds it layer by layer from materials such as resin, plastic, or even powdered stone. Yet, in archaeology, this process does far more than produce a replica. It can recreate entire objects that no longer exist, reconstructing what time, war, or nature have destroyed.

One of the most remarkable examples of this process is the reconstruction of the Palmyra Arch in Syria. After ISIS destroyed the ancient monument in 2015, researchers from Oxford and Harvard used thousands of photos and laser scans to rebuild a precise 3D model. Within months, they printed a two-thirds scale replica using marble dust and resin, allowing the world to once again walk beneath an icon of Roman architecture — even as the original lay in ruins. It wasn’t just a symbolic victory over destruction; it was proof that lost heritage could be digitally resurrected.

But 3D printing doesn’t stop at large monuments. In museums and labs, scientists are using the technology to replicate fragile artifacts that can’t be handled or displayed. Ancient manuscripts, crumbling bones, and even mummified remains can now be scanned in ultra-high resolution and reprinted safely. This allows students, historians, and visitors to touch and study objects that would otherwise remain locked away. In some cases, it even enables “virtual restoration” — digitally repairing cracks or missing pieces before printing a flawless reconstruction, revealing how the artifact might have looked thousands of years ago.

Perhaps even more fascinating is how 3D printing is helping to reverse-engineer the past. When only fragments of an artifact survive, algorithms can compare them with databases of similar objects to predict what the missing portions looked like. Then, the missing sections can be printed and seamlessly joined with the original. In this way, an incomplete Greek vase, a broken cuneiform tablet, or an eroded statue can be made whole again — without altering the fragile original.

The implications go far beyond archaeology. When a piece of cultural heritage is digitized, it becomes immortal in a sense. Digital archives of scanned artifacts are now being stored in international databases like the Global Digital Heritage project, ensuring that even if the physical object is lost, the data — and the ability to recreate it — will endure. It’s a kind of “backup drive” for humanity’s collective memory.

Of course, there are debates. Some argue that 3D reproductions blur the line between authentic and artificial. Can a printed replica ever carry the same weight as the original, forged by ancient hands? Others worry about the potential misuse of the technology — from counterfeit artifacts to forgeries that could deceive collectors and scholars alike. Yet most archaeologists agree that the benefits far outweigh the risks. Every copy is also a safeguard, every scan a new opportunity for discovery.

Looking ahead, advances in biomaterials and nanoscale printing could make replicas indistinguishable from the originals, both visually and in texture. Some researchers are even exploring “smart reconstructions” — printed artifacts embedded with sensors that track environmental changes or stress, helping preserve both the replica and the authentic piece.

What was once lost might soon never be lost again. Through 3D printing, history is no longer just uncovered — it’s rebuilt, reimagined, and reconnected to the present. The ruins of yesterday are becoming the blueprints of tomorrow, one printed layer of memory at a time.